We offer Mercedes sprinter van with innovative safety features and superior capabilities designed to fit healthcare professionals’ requirements, no matter what they may be. Get one operatory Mercedes sprinter dental van with 1-year parts and labor warranty.

The Mercedes sprinter van is known as the complete package – tough, powerful, efficient and flexible. So, it can handle any condition your work day requires. Mercedes sprinter van retain their value over time, so, the healthcare professionals like you; get the most for your investment. Get Marcedes sprinter dental van with Beaver state dental patient chair, Beaver state dentist stool, Aseptico AMC-25 self-contained cart & other dental equipment.

USED 2020 Mercedes Sprinter Extended Cab Van with 12,000 miles and balance of factory warranty per below specifications, cab & chassis specifications attached per drawing # 1001132C for conversion to a dental clinic with the following specifications:

Note: Some specifications may change due to van availability.

| Mercedes Sprinter Van Up Fitted to a Dental Clinic Plus Applicable Taxes FOB Amelia, Ohio |

|

| Dental Equipment Included: | |

| Beaver state dental Patient Chair. #Epic with Slings | |

| Beaver state Led Ceiling mount light. | |

| Beaver state dentist stool | |

| Beaver State Assistant stool | |

| Aseptico AMC-25 self contained cart | |

| Tuttnauer Autoclave | |

| SharperTec 1.5 Gal ultrasonic cleaner | |

Dental Equipment Options

| Portable X -ray MASTERLINK Cocoon |

| Optional Portable X-Ray NOMAD |

| Optional Digital Sensors #1 & #2, |

| Optional Apixia Digital Phosphor Plate Scanner |

Van Options

| 1) Powered 8’ awning installed |

| 2) 18,000 BTU LG Mini-split HVAC system |

The wall construction shall consist of the following:

The customer entry door shall be the side sliding door as provided by Mercedes Sprinter with accessory exterior running board step installed. The door will be insulated and covered with panel to match interior décor.

The left rear door shall be insulated and covered with panel to match interior décor.

The sealed composite floor will allow no external moisture or mold buildup inside coach. Screw holes shall be sealed and sanded to smooth as required to prevent moisture from entering body and to provide a permanent smooth surface for installation of floor covering. The floor covering shall be easy clean wood grain planck vinyl.

Body shall be insulated with up to 3” thick closed cell foam insulation and fiberglass batt insulation with an R-factor of up to 20 for ceiling, sidewalls and doors to maintain the most comfortable working environment for staff and patient.

A step slip resistant running board shall be installed at right side sliding entry door, and a running board shall be installed at driver door for ease of entry and exit.

All interior cabinetry shall be solid wood fronts with 5 ply plywood sides. All cabinet doors will include latches to prevent opening while in transit. Three large two-door wall cabinets are included for accessory and supplies storage located above left wheel well protrusions and above generator housing.

The ceiling shall be an easy clean vinyl covered plywood with (2) flush mounted high tech LED string lights, front to rear with dimmer.

Shall be a 120VAC single phase system rated for anticipated load. System shall include a 60A/120vac rated distribution panel configured with UL listed type circuit breakers. Circuit breakers shall be sized per component manufacturers’ recommendation.

System shall be wired using 12 gauge, 3-conductor (12/3), 600V rated, UL approved, MC commercial cable. All wiring shall be color-coded: black = hot, white = neutral, and green = ground. Additionally, wiring shall be labeled listing circuit number and/or designation at all termination points. All wiring shall adhere to applicable NEC and FMVSS regulations.

Wiring shall be supported on 16” centers with insulated, non-conductive clamps. Wire bundles shall be tied with trimmed nylon ties. Extreme care shall be taken to prevent chafing, abrasion, and exposure to high heat. Wiring run in external areas shall be encased in liquid tight conduit to further protect against the elements and mechanical damage.

Specific number and type of receptacles shall be determined during the pre-construction process.

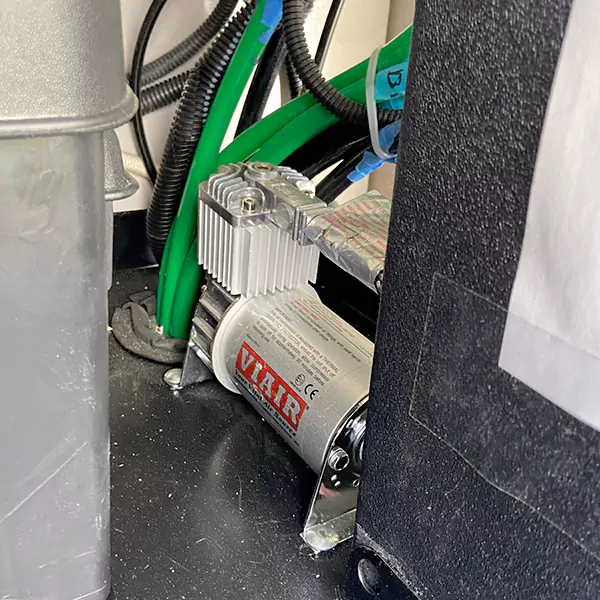

Shall be a 12VDC, negative ground system rated for anticipated conversion load. System shall include fuse panel using blade type fuses. All circuits shall be protected from over current by fuses rated for a minimum of 125% of anticipated load. 12VDC functions shall be clearly designated by printed labels. Wiring shall be labeled listing circuit number and/or designation at all termination points.

Generator battery system shall include one (1) deep-cycle gel cell sealed battery mounted inside van in a battery case. (1) 10AMP automatic battery maintainer to prevent battery overcharging.

System shall provide separate generator battery charging during operation periods when the vehicle engine is not running to prevent depletion of generator battery power.

All high-current battery cabling shall utilize full-length cable runs sized to load. Terminal ends shall be crimped with manufacturer recommended tooling and sealed using color-coded wrap.

All added wiring for 12VDC load runs shall be AWG 8, 10, 12, and 14, and conform to MIL-W-1678D type D. Wire terminals used shall conform to MIL-T-7928. Terminals shall be insulated with insulation grip, Type II, Class 2, and crimped with tooling recommended by manufacturer.

All added wiring shall be supported on 12” centers and bundles shall be tied with trimmed nylon ties. Entire system shall be installed to modern US automotive standards using best practices available at time of installation. Plastic/rubber grommets and/or dielectric sealants shall be used to protect wiring and/or looms where they pass through sheet metal, bulkheads, or structural supports. Convoluted polyethylene tubing shall be used to protect against chafing and abrasion where required. Extreme care shall be exercised to provide for easy serviceability of the system in future years. Extreme care shall be taken to avoid the engine manifold, engine exhaust, muffler, or any high-heat items that may subject the wiring to severe overheating during long periods of operation. These shall be the minimum acceptable wiring standards.

Pre-wire for dental application included.

Install wood grain vinyl planck floor covering.

7.5 KW diesel Onan Generator shall be installed directly inside rear doors to include a sound deadened enclosure. Generator fuel line will be tied into the existing chassis fuel tank to allow 3” of fuel to remain in tank. This is to assure the chassis fuel tank cannot be run out of fuel totally.

The generator shall be mounted on the right rear vehicle floor just inside the left rear door with rear access. Generator installation shall be in full accordance with manufacturer’s recommendations including any air flow restrictions associated with the installation method. The generator exhaust pipe shall be routed to exhaust on roadside away from entry door.

The sound-insulated enclosure will be built to accommodate the required generator. The enclosure will be securely tied and sealed to the floor and will allow hinged access to the generator. Generator shall have one swing-up door with latch for ease of access, minimizing re-circulation preventing overheating and meeting all manufacturer’s requirements. The generator enclosure shall be insulated for elimination of heat, noise, and fumes to the coach area through walls and/or flooring without interfering with necessary airflow.

Generator start, stop switch and hour meter shall be located in a diagnostic suite cabinet for easy accessibility.

One (1) 13,500 BTU wall mounted central heating and air conditioning system with overhead delivery is provided. A 5200 btu floor heater is included

One heavy duty commercial four point hydraulic stabilization system with automatic/individual controls is located conveniently within the dental suite.

(2) lengths of 12VDC adjustable LED string lights shall be mounted flush with the ceiling, full length each side for a bright working space

As provided by Mercedes Sprinter

The dental procedure area will be constructed according to floor plan. The area will include the following:

Heavy-duty rubber covered 45’ long SO 10-2 with ground shoreline cord shall be provided. Generator/shore power transfer switch or equivalent is also provided.

Interior wall storage cabinets will be provided according to floor plan drawing # 1001134D as well as multiple cabinets about sink area

Full body graphics per customer furnished artwork is included

Wrap around windshield panel included

We sell, rent and export all types of mobile vehicles, including medical van, medical coaches, medical trailer, mobile dental clinics, mobile dental vans, new & used dental coaches, refurbished medical coaches & trailer and dental office in modified ocean type containers globally. We also provide medical trailer and medical coaches for rental in the USA, Canada, Mexico, and more countries.

Join us to stay updated with our latest blog updates, news, tips, guide and annoucements!